Polyolefin Catalyst Market Share, Size, and Growth Analysis 2025-2033

IMARC Group's report titled "Polyolefin Catalyst Market Report by Type (Ziegler-Natta Catalyst, Single Site Catalyst, Chromium Catalyst, and Others), Classification (Polypropylene, Polyethylene, and Others), Application (Injection Molding, Blow Molding, Films, Fibers, and Others), End Use Industry (Automobile, Construction, Healthcare, Electronics, Packaging, and Others), and Region 2025-2033", The global polyolefin catalyst market size reached USD 2.7 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 3.8 Billion by 2033, exhibiting a growth rate (CAGR) of 3.9% during 2025-2033.

For an in-depth analysis, you can refer sample copy of the report: https://www.imarcgroup.com/polyolefin-catalyst-market/requestsample

Factors Affecting the Growth of the Polyolefin Catalyst Industry:

- Growing Demand for Lightweight and Durable Materials in Packaging and Automotive Industries

The demand for lightweight, long-lasting, and cost-effective material solutions from the packaging and automotive industries is one of the foremost drivers for this market since polyolefins, such as polyethylene (PE) and polypropylene (PP), have desirable mechanical properties, chemical resistance, and versatility to them. Polyolefins are widely used in the packaging industry for producing films, containers, and wraps for flexible packaging solutions in food, beverage, and consumer goods. However, polyolefins have also been increasingly absorbed into the automotive industry, with an essential role in lightening vehicles for improved fuel efficiency and compliance with stringent emission regulations. Such a dramatic increase in polyolefin production is directly related to the increasing procurement levels of catalysts, which are required to improve polymerization efficiencies and access property-specific polymers. The most advanced catalyst technologies in the market, namely Ziegler-Natta and metallocene catalysts, favor the manufacturing of polyolefins shown to possess their specific superior characteristics and subsequently fuel market growth. Sustained by the above-mentioned factors, the demand for innovative catalysts will increase rapidly as industries today continue to exert much emphasis on sustainability and performance.

- Technological Advancements in Catalyst Design and Polymerization Processes

It is apparent that the paradigm of the polyolefin catalyst market has altered due to technological innovations in catalyst design and polymerization processes. The development of metallocene catalysts has brought polyolefin manufacturing into a new dimension, wherein greater control over polymer structures and properties can be achieved. Very clearly, these technologies lead to polymers with improved clarity, toughness, and processability in meeting the changing requirements of various sectors. Improvements in formulation also promise better yields at lower production costs and eco-friendliness, which are comparable to the globally accepted sustainability targets. Single-site catalysts and hybrid systems have further widened the application range of polyolefins-from high-performance films to special automotive components. Another area of emerging research is catalyst recycling and regeneration techniques, which present the cost-benefit to the environment. While manufacturers are relentlessly putting efforts into making themselves more competitive and compliant, consistent innovations in catalyst technology will remain a driving factor toward market growth.

- Impact of Environmental Regulations and Sustainability Initiatives on Market Dynamics

In a fast-changing environment, polyolefin catalyst is becoming more and more dependent on strict local or international environmental regulations and sustainability initiatives that result from plastic waste and carbon lowering emissions. Local and international governments and agencies are developing stringent regulations to prevent plastic pollution, to promote recycling, and to incentivize the use of eco-friendly materials. In turn, such regulations have made it imperative for manufacturers to invest in sustainable catalyst technologies which allow the polymerization of recyclable and biodegradable polyolefins. In addition, the definition of a circular economy increases the demand for catalysts that allow the use of recycled feedstock in polyolefin production. The firms are also going to bio-based polyolefins that need specialized catalysts for polymerization. Manufacturing processes with reduced carbon footprints also lead to energy-efficient catalysts and processes minimizing greenhouse gas emissions. With increasing pressure on industries from environmental considerations, the polyolefin catalyst industry is about to take a new high in its paradigm shift focusing more on sustainable innovation and compliance with evolving regulatory standards.

We explore the factors propelling the polyolefin catalyst market growth, including technological advancements, consumer behaviors, and regulatory changes.

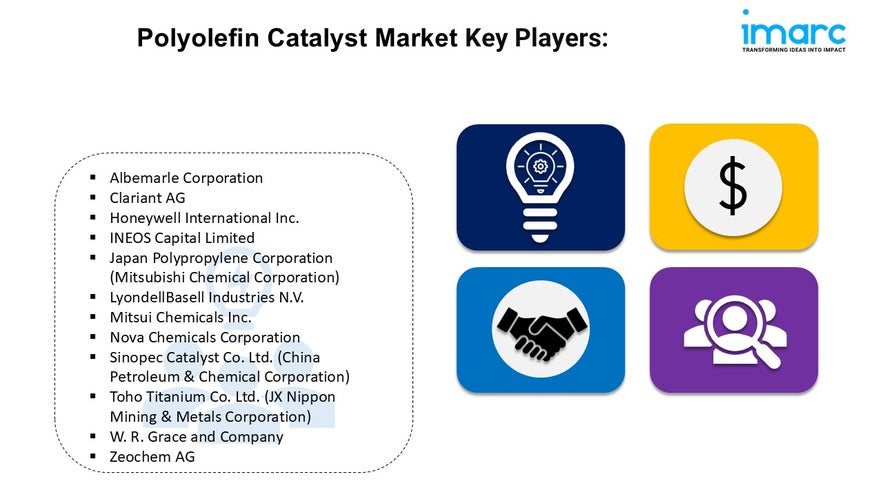

Leading Companies Operating in the Global Polyolefin Catalyst Industry:

- Albemarle Corporation

- Clariant AG

- Honeywell International Inc.

- INEOS Capital Limited

- Japan Polypropylene Corporation (Mitsubishi Chemical Corporation)

- LyondellBasell Industries N.V.

- Mitsui Chemicals Inc.

- Nova Chemicals Corporation

- Sinopec Catalyst Co. Ltd. (China Petroleum & Chemical Corporation)

- Toho Titanium Co. Ltd. (JX Nippon Mining & Metals Corporation)

- W. R. Grace and Company

- Zeochem AG

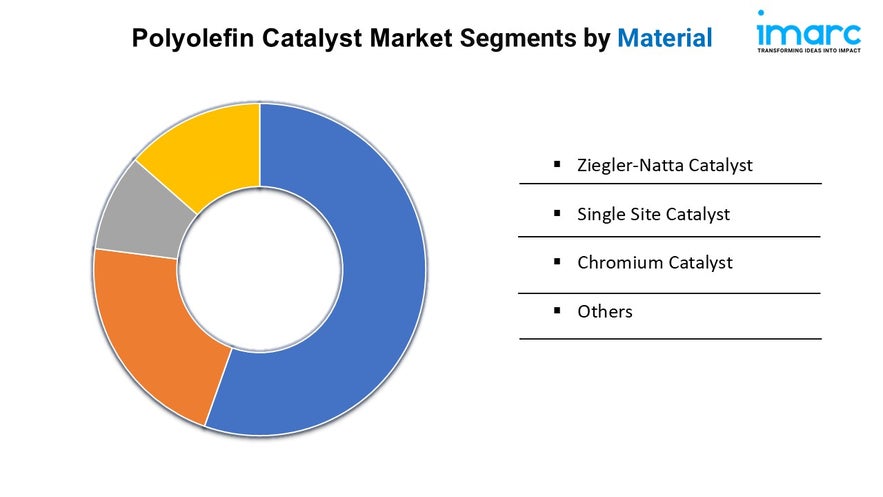

Polyolefin Catalyst Market Report Segmentation:

- Ziegler-Natta Catalyst

- Single Site Catalyst

- Chromium Catalyst

- Others

Ziegler-Natta catalyst represents the largest segment as it improves polymerization processes by providing high polymerization rates and enhanced control over molecular weight distribution.

By Classification:

- Polypropylene

- Polyethylene

- Others

Polyethylene holds the biggest market share on account of its flexible and lightweight nature.

By Application:

- Injection Molding

- Blow Molding

- Films

- Fibers

- Others

Films account for the largest market share due to the rising focus on enhancing product visibility and branding.

By End Use Industry:

- Automobile

- Construction

- Healthcare

- Electronics

- Packaging

- Others

Packaging exhibits a clear dominance in the market, driven by the increasing need to preserve the quality and freshness of various packaged products.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific enjoys a leading position in the polyolefin catalyst market, which can be attributed to the rising focus on sustainability in the plastics industry.

Global Polyolefin Catalyst Market Trends:

In recent history, there has been an emergence of key developments influencing the expansion path of the polyolefin catalyst market. Perhaps one of the significant demand trends is the growing adoption of metallocene and single site catalysts, which are designed to provide better control over the properties of the resultant polymers, thereby enabling the high-performance material properties development. This demand is fueled primarily by the need for advanced polyolefins with superior clarity, strength, and processability in different applications, including packaging, automotive, and healthcare. Another trend is dedicated to sustainability and environmental responsibility, with catalyst manufacturers bringing in catalysts that are meant to be used to develop recyclable and compostable polyolefins. This trend is also gaining momentum in terms of incorporation of scraps into polyolefin processes under a circular economy. The technological advancement in the design of catalysts and polymerization techniques are starting to fire significant efficiency, cost-saving elements, and less environmental impact. Also, the polyolefin catalyst market is shifting between regions. Emerging economies in Asia-Pacific are becoming critical industrial and consumption hubs over time, due to rapid and continued intensive industrialization and infrastructure development. In brief, the market is continuously responding to innovations in technology, environmental parameters, and consumer behavior.

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

Other interesting blogs

Chasing Waterfalls in Iceland

Iceland is spectacular in so many ways and Icelandic nature is quite unique with its vast landscape, volcanic activity, geothermal areas, glacier lagoons and sceneries, black sand beaches and spectRead moreSænautasel Turf House in the Highland of Iceland

In my search for turf houses around Iceland, I visited Sænautasel, which is a rebuilt turf house on Jökuldalsheiði heath in the highland of Iceland. It is, in my opinion, an extremely cute turf hoRead moreLupines in Iceland: Beauty, Controversy, and Environmental Impact

Iceland’s striking landscapes are known for their stark beauty—volcanic deserts, lava fields, glaciers, and black sand beaches. Among these natural wonders, visitors in summer may notice vast fieldsRead more

Download Iceland’s biggest travel marketplace to your phone to manage your entire trip in one place

Scan this QR code with your phone camera and press the link that appears to add Iceland’s biggest travel marketplace into your pocket. Enter your phone number or email address to receive an SMS or email with the download link.